What Sets Apart Electric Car & Conventional Car Steering?

Electric Car Steering: What sets It Apart from Conventional Cars?

As we accelerate towards a future fueled by sustainability, electric cars are rapidly becoming the stars of the road. This shift brings with it a wave of technological advancements, particularly in how we steer these innovative machines. The steering system, a critical interface between driver and vehicle, is undergoing a fascinating evolution. This raises a compelling question: How do electric car steering mechanisms differ from those in traditional gasoline-powered vehicles? Learn how understanding these differences can help you maintain your vehicle, regardless of its power source.

What is a Steering System?

The steering system is a critical component of any vehicle, responsible for giving the driver control over its direction. It translates the rotational movement of the steering wheel into the lateral movement of the wheels. In traditional vehicles, the steering system usually involves a mechanical linkage between the steering wheel and the wheels, allowing the driver to guide the vehicle smoothly.

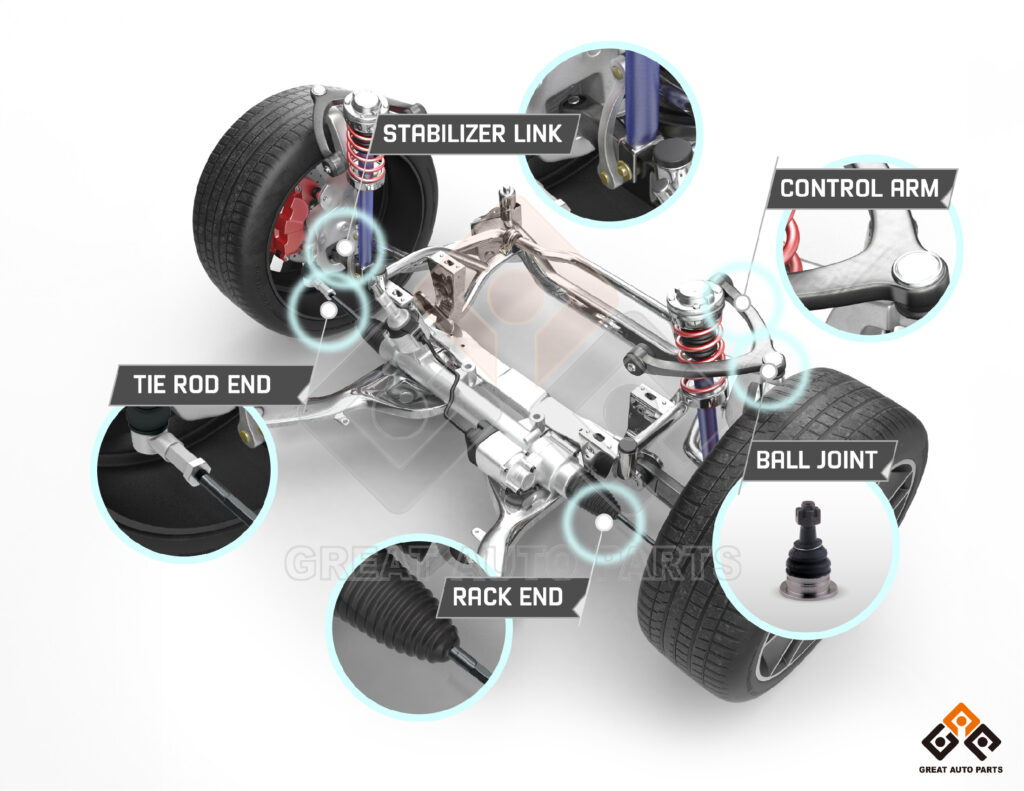

Key Components Inside a Steering System

- Stabilizer Links: These connect the sway bar to the suspension components, minimizing body roll during cornering.

- Tie Rod End: This links the steering knuckle to the rack-and-pinion or steering box, transmitting force to the wheels. For more details on tie rod ends, you can check out our article on The Vital Role of Tie Rod Ends in Your Car’s Steering.

- Ball Joint: This connects the control arm to the steering knuckle, allowing for flexible movement. Discover more about their importance in our piece, Difficulty in Steering? It’s Time to Replace the Suspension Joints.

- Rack End: This connects the outer tie rod to the steering rack, contributing to steering responsiveness.

- Control Arm: This attaches the steering knuckle to the vehicle’s frame, providing support and facilitating controlled movement.

Together, these components ensure that your steering inputs translate efficiently, resulting in a smooth and controlled driving experience.

How Does Electric Car Steering Differ?

In an electric car steering system, traditional mechanical linkages are often replaced by electronic components. Electronic sensors and actuators take center stage, interpreting the driver’s input and directly controlling the movement of the wheels. This shift towards “steer-by-wire” technology enhances precision, responsiveness, and opens avenues for innovative features like customizable steering response. Furthermore, while conventional cars rely on hydraulic power steering, electric cars typically use electric power steering (EPS), which consumes less energy.

Are there Design Variations in Electric Car Steering Components?

Yes, subtle variations in design and materials often exist between the steering systems of electric cars and conventional cars. For instance, components like sway bar links, tie rod ends, ball joints, inner tie rods, and control arms in an electric car may feature adaptations to accommodate the vehicle’s unique characteristics and requirements. Manufacturers frequently optimize these parts for different weight distribution, power delivery, and overall driving dynamics inherent to electric cars. You can explore more about automotive component design at sites like SAE International.

Maintenance Differences: Electric Car vs. Conventional Steering

Electric cars generally require less maintenance in their steering systems due to their reduced reliance on mechanical components. With fewer moving parts and the absence of hydraulic fluids, there’s less wear and tear. Conversely, conventional cars, with their intricate mechanical linkages and hydraulic systems, often demand more regular attention and maintenance to ensure optimal performance. This can lead to lower long-term ownership costs for electric car owners in terms of steering system upkeep.

Specialized Parts and Weight Distribution in Electric Cars

Indeed, electric cars often exhibit different weight distribution because of battery placement. This unique distribution can lead to the development of specialized auto parts within the steering mechanism. These specialized parts ensure the system effectively handles the distinct challenges posed by the shifted weight, helping to maintain the precision and reliability of the steering in electric vehicles. Automotive engineering firms continuously innovate in this area to optimize handling.

Steering into The Future With Quality Parts

As we conclude our exploration of the differences in steering systems between electric cars and conventional cars, it’s clear that precision and quality in automotive parts play a crucial role in this technological evolution. This is where Great Auto Parts Industrial CO., LTD., based in Taiwan since 1988, emerges as a leader in the field. With over three decades of expertise in manufacturing automotive CNC machined components, Great Auto Parts has established itself as a beacon of excellence in the industry.

Their extensive range of products, including suspension and steering parts like front outer tie rod ends, upper and lower ball joints, car steering racks, and rear stabilizer bar links, caters to a diverse array of vehicles. Whether you are navigating the complexities of electric vehicle technology or maintaining the reliability of conventional cars, Great Auto Parts is your go-to source for steering and suspension components that define excellence.

For more information on automotive trends and innovations, consider visiting Automotive News.