Driving the Future of Suspension: Our Research & Development Commitment

With decades of experience navigating the dynamic automotive sector, our journey has been consistently propelled by a relentless commitment to robust aftermarket suspension parts Research and Development (R&D). Our R&D isn’t just a department; it’s the heartbeat of our innovation and the engine that drives our enduring success. Ultimately, this dedication allows us to consistently push the boundaries of what’s possible in auto parts performance and design.

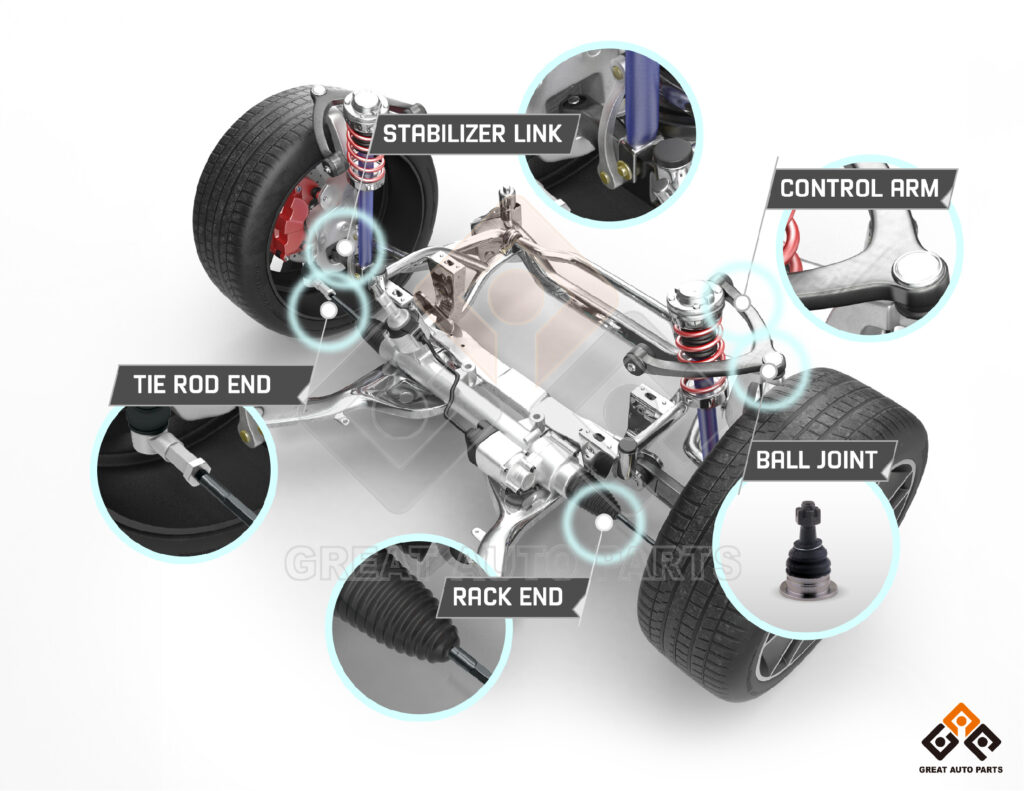

Precision-Engineered Aftermarket Suspension parts and Steering Solutions

At the heart of our company is an R&D department, a true hive of innovation. Here, we transform groundbreaking ideas into tangible breakthroughs that redefine automotive capabilities. We understand that every component, no matter how small, plays a critical role in a vehicle’s overall performance and safety. That’s why we meticulously develop our assembly suspension parts and steering parts from original equipment manufacturer (OEM) samples, ensuring unparalleled precision, compatibility, and performance.

Quality You Can Trust: Meeting Global Automotive Standards

We take pride in our global reach and unwavering dedication to quality. All our products adhere to rigorous international standards, including the American SAE J490 and J491 specifications, along with stringent German automotive aftermarket quality standards. This commitment to global excellence ensures our aftermarket suspension parts not only meet but exceed the expectations of a diverse international market.

Currently, we offer a comprehensive selection of solutions for European, American, Japanese, and Korean cars. With an extensive inventory of up to 2,500 distinct items and an additional 150 new parts developed each year, we continuously expand our offerings to meet the evolving demands of the automotive industry.

The Future of Automotive Innovation Starts Here

By continually investing in our R&D capabilities and adhering to the highest quality benchmarks, we are doing more than just manufacturing aftermarket suspension and steering auto parts—we are shaping the future of driving. Our relentless pursuit of innovation ensures that our partners and customers always have access to cutting-edge, reliable, and high-performance automotive solutions.

Investing in Future Technologies

For years, we have consistently channeled over 3% of our annual turnover directly into Research & Development (R&D). This is not just an expense; it is a strategic investment and a testament to our unwavering commitment. As a result, we can both enhance our existing product lines and ensure our new developments consistently exceed evolving market demands and customer expectations. This substantial dedication of resources empowers us to stay at the forefront of automotive innovation.

Continuous Improvement Through Advanced R&D

Our significant investment in R&D has been a catalyst for continuous improvement in our products’ physical properties and process characteristics. This meticulous focus directly translates into the high-quality advancements our customers trust implicitly. Ultimately, we understand that superior performance and durability are non-negotiable in the suspension and steering parts sector, and our R&D efforts are meticulously geared towards delivering just that.

Reducing Costs, Maximizing Value

At our core, we fully embrace our responsibility to our customers. This fuels our relentless pursuit of innovative ways to reduce product costs without ever compromising on quality. We achieve this through a multifaceted approach, including:

- Adopting innovative ways to increase productivity

- Developing highly efficient processing methods

- Strategically reducing raw material costs

- Continuously improving overall work methods

- Diligently eliminating scrap wherever we find it

By meticulously optimizing every stage of our operations, from concept to delivery, we ensure our customers receive the highest value for their investment. Ultimately, our commitment to sustainable innovation isn’t just about what we create; it’s about how we create it.

Comprehensive Product Testing Services

We rigorously test our automotive components for safety and effectiveness. Our comprehensive evaluations of performance and durability ensure every product meets top industry standards, consistently exceeding what our customers expect.

Ensuring Product Safety and Efficiency

Your safety is our top priority. We use advanced testing techniques to rigorously assess the functionality and safety of our products. As a result, every item we produce not only meets, but frequently exceeds, all required safety standards.

Impact Testing: Our Rigorous Approach

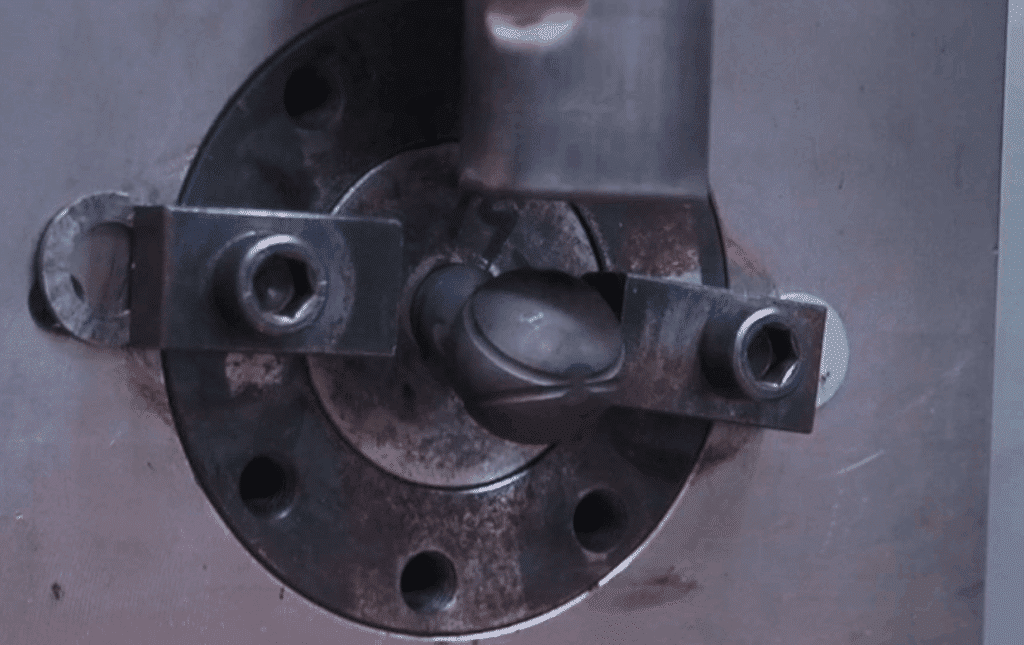

Pull-out Test

Pull-out Test is a cornerstone of our quality assurance strategy. It evaluates the structural integrity and retention strength of the ball stud within its housing, which is vital for ensuring the safety, longevity, and resilience of our steering and suspension components under extreme load.

Material Metallurgical Microscope Research

Our commitment to excellence begins with the materials themselves. That’s why we use state-of-the-art metallurgical microscopes to thoroughly examine their internal structure and integrity. Consequently, we can guarantee that every product batch meets and even exceeds our stringent quality standards.

Expertise in Automotive Parts Manufacturing

Our extensive experience in automotive parts manufacturing drives our ability to innovate and maintain industry leadership, shaping our approach from design to delivery.

For three decades, we’ve led the automotive aftermarket in suspension and steering parts manufacturing. This extensive experience has not only established us as industry leaders but has also given us a profound understanding of market demands. As a result, our invaluable insights directly enhance every step of our R&D and design processes.

Professional Advice and Planning

We provide expert advice and process planning tailored to each customer’s specific requirements. Our team collaborates closely with clients to convert their needs into practical, effective solutions.

Each automotive part we develop starts with a concept designed to address specific customer needs or market gaps. Our process from concept to road involves multiple phases of design refinement, thorough testing, and integration of customer feedback, ensuring that the final product performs flawlessly.

Custom Process Planning for Your Needs

Recognizing the unique challenges and requirements of each client, we specialize in bespoke process planning. This tailored approach allows us to design and implement manufacturing processes that are perfectly aligned with the specific needs of our clients, maximizing efficiency and product quality.

ESG Declaration and Corporate Sustainability

Our dedication to Environmental, Social, and Governance (ESG) principles is deeply embedded in every aspect of our operations, reflecting our unwavering commitment to sustainable and ethical practices across the board. By integrating environmental stewardship, social responsibility, and strong governance, we strive to achieve sustainable growth that benefits our stakeholders, the community, and the environment. In October 2025, we proudly obtained ISO 14001:2015 certification, marking a solid step forward toward a sustainable environmental future and reinforcing our determination to build a resilient, responsible, and forward-looking organization.

Environmental Stewardship

Our commitment to the environment is embedded in every aspect of our operations. We actively pursue reductions in our environmental footprint through several strategic initiatives:

- Resource Efficiency: We continuously improve our manufacturing processes to increase efficiency and reduce waste. This involves optimizing our use of materials and energy throughout our production cycles, ensuring that we not only comply with environmental regulations but also exceed them.

- Sustainable Materials: We are dedicated to adopting more sustainable and recyclable materials in our product designs and manufacturing processes. This commitment not only helps reduce the ecological impact of our products but also caters to the growing consumer demand for environmentally friendly products.

- Innovation in Product Design: Our R&D department plays a crucial role in enhancing the environmental performance of our products. By focusing on developing products that are not only effective but also ECO-friendly, we ensure that innovation aligns with sustainability goals.