Navigating Supply Chain Volatility with Auto Parts Flexible MOQ and Customization

The Modern Dilemma: Balancing Inventory Risk and Market Demand

In the global automotive aftermarket, procurement managers and distributors face a persistent and growing challenge: the delicate balancing act between supply and demand. Traditionally, the manufacturing industry has been driven by high-volume economies of scale, leading to rigid Minimum Order Quantities (MOQs). For many businesses, this creates a significant financial burden.

Common Challenges Faced by Procurement Teams:

- Capital Immobilization:

High MOQs force businesses to tie up significant capital in slow-moving stock, limiting their ability to invest in new market opportunities. - Warehouse Overload:

Excessive inventory leads to increased storage costs and the risk of component degradation or obsolescence over time. - Inflexible Lead Times:

Large-scale manufacturers often prioritize massive orders, leaving smaller or urgent custom requests at the back of the queue. - Supply Chain Fragmentation:

Dealing with multiple vendors for different components increases administrative errors and complicates quality control.

The modern market requires Auto Parts Flexible MOQ and Customization—an agile approach where production is aligned with real-time market fluctuations rather than outdated manufacturing constraints.

Identifying Core Challenges in Specialized and Performance Part Procurement

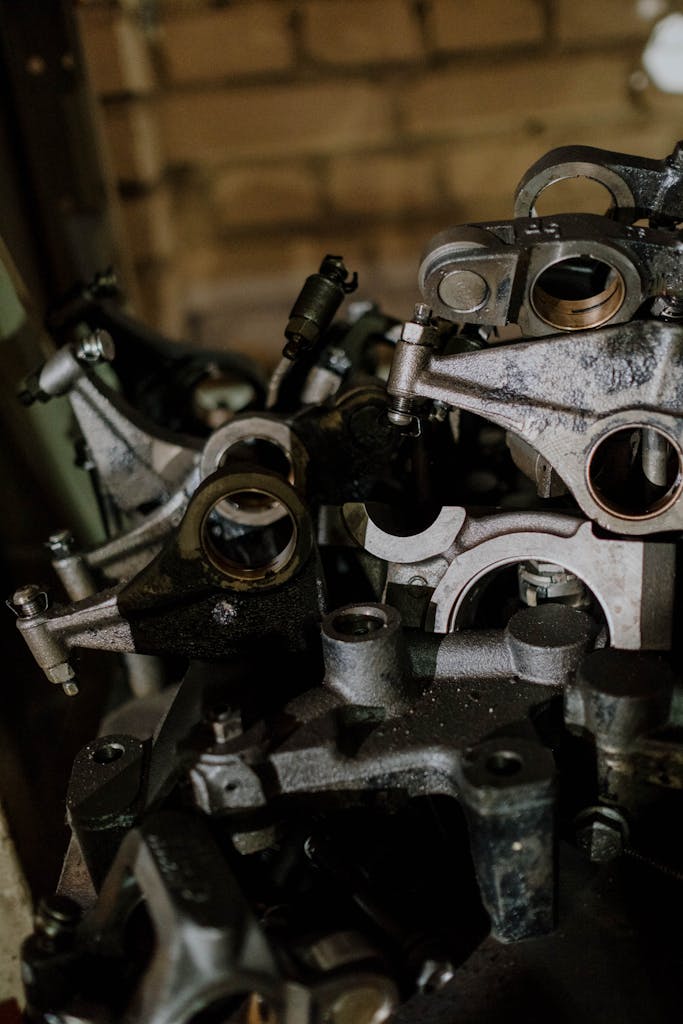

Beyond standard inventory, the demand for specialized or custom-engineered parts introduces even more complexity. This is particularly evident in the performance and modified car market (Aftermarket Tuning), where vehicle owners demand unique specifications that standard production lines cannot provide.

Whether it is a reinforced control arm for a lowered suspension or a specialized ball joint for high-performance racing, most large-scale manufacturers are unwilling to adjust their lines for anything less than thousands of units. This lack of flexibility stifles innovation. The implementation of Auto Parts Flexible MOQ and Customization is the difference between capturing a niche market opportunity and being left behind by more agile competitors.

The Synergistic Approach: One-Stop Procurement Advantages

A truly effective supply chain solution involves a single-source partner capable of providing a wide range of component options. The primary advantage of this One-Stop Shop model is the ability to consolidate diverse part requirements, which directly impacts your bottom line.

| Key Advantage | Strategic Benefit for Your Business |

| Logistics Consolidation | Combines multiple part types into a single shipment, increasing volume per load. |

| Transportation Economy | Reduces landed costs per unit by optimizing shipping container space and efficiency. |

| Quality Consistency | Ensures all chassis components (Rack Ends, Ball Joints, etc.) meet the same engineering standards. |

| Simplified Management | Reduces administrative overhead by dealing with a single point of contact for diverse orders. |

| Lead Time Reduction | Synchronized production schedules across multiple part categories for faster delivery. |

This logistical optimization allows for better quality control across the entire steering system while simplifying the documentation and customs process.

How Great Auto Parts Empowers Your Business

At Great Auto Parts, we have spent over 30 years perfecting the balance between high-quality engineering and manufacturing flexibility. We bridge the gap for businesses that need precision without the burden of excessive inventory. Our facility is uniquely equipped to deliver Auto Parts Flexible MOQ and Customization through:

- Custom Solutions for Modified Vehicles: We provide specialized customization services for performance and modified car parts, catering to the unique technical requirements of the tuning market.

- Precision CNC Machining: We offer a highly competitive MOQ of 500pcs for CNC machined parts, ensuring exceptional accuracy for your most demanding specifications.

- Custom-Engineered Solutions: For parts tailored to your unique designs, our MOQ ranges from 300 to 500pcs, depending on the complexity of the requirements.

- Total Customization: We customize every order based on your application environment, dimensions, material selection, and quantity.

- One-Stop Convenience: Our extensive technical expertise covers a vast range of parts, including Rack Ends, Tie Rod Ends, Control Arms, Stabilizer Links, Ball Joints, and Bushings. Our ability to offer diverse part selections helps you maximize shipping efficiency and simplify procurement.

Are you currently searching for specific components or do you have a unique customization requirement for your next project? Our team is ready to help you optimize your supply chain.